Providing the fastest processing speed to resolve inefficiencies in manufacturing plants throughout the world.

Please contact us about reducing your cycle time.

-

INQUIRIES

Contact us by email

-

+81(0)0533-76-3381

Operating hours: 8 AM to 5:30 PM (Monday~Friday)

-

Machines that significantly reduce the cycle time

-

Automation and robotization of production facilities

-

Help with creating a robust and lean manufacturing plant by focusing the manufacturing line into a more compact setup

Please contact us about reducing your cycle time.

-

INQUIRIES

Contact us by email

-

+81(0)0533-76-3381

Operating hours: 8 AM to 5:30 PM (Monday~Friday)

PRODUCT

-

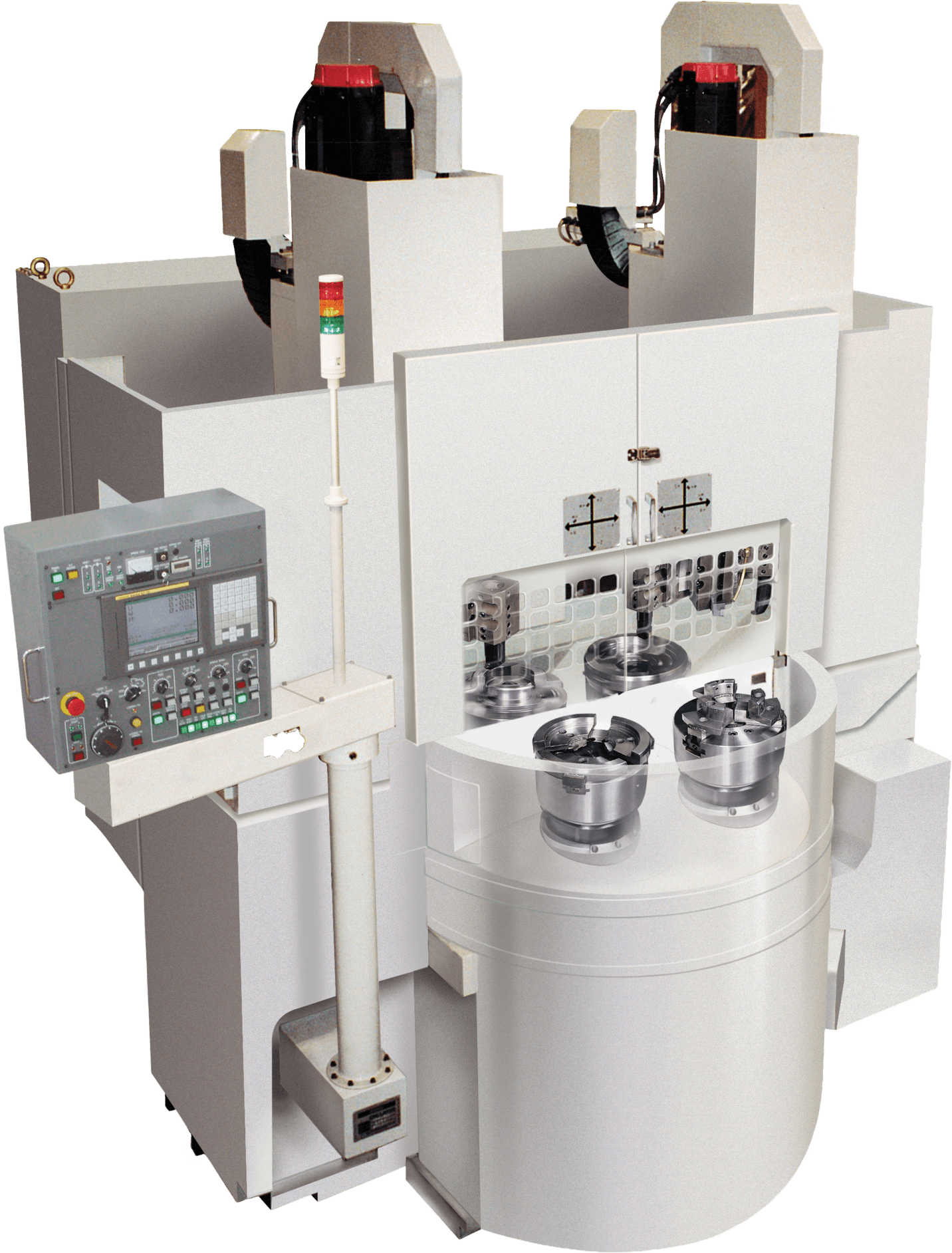

2SI-6/8

2SI-6/8 Loading time of “zero” seconds. Packages are available with robots due to its distinguished robot compatibility. It is also very easy to use as a manual loading machine.

-

2SI-10

Large parts and long shaft parts require a long non-cutting time for loading and chucking.

This machine is optimal for this kind of work.

-

2SI-8 Mk-Ⅱ

“Zero loading” and OP10 and OP20 interprocess machining eliminate lost time, which can help you who want to reduce cycle time.

3-Spindle 2NC lathe

The best option for multitasking mass production when used as a 6-spindle 4-Turret lathe after linking two machines.

-

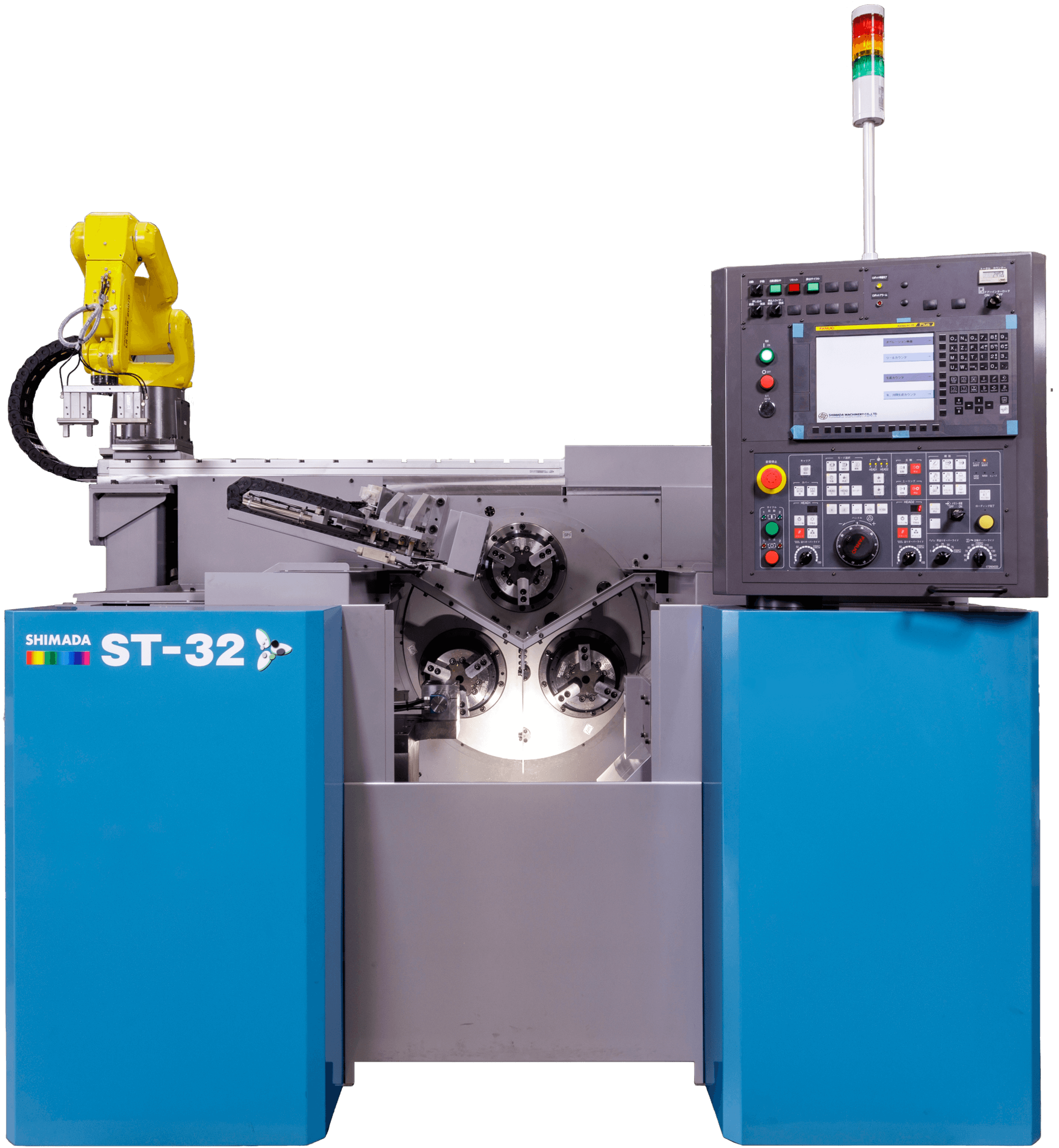

ST-32

This machine has three stations, divide hole process into 3 rooms. A maximum of 20 cutting tools can be mounted for single operation.

4-Spindle(4-Spindle 2NC lathe)

Provides extremely higher performance for productivity despite using the same amount of space and operation methods as a 2-spindle 2-saddle lathe.

-

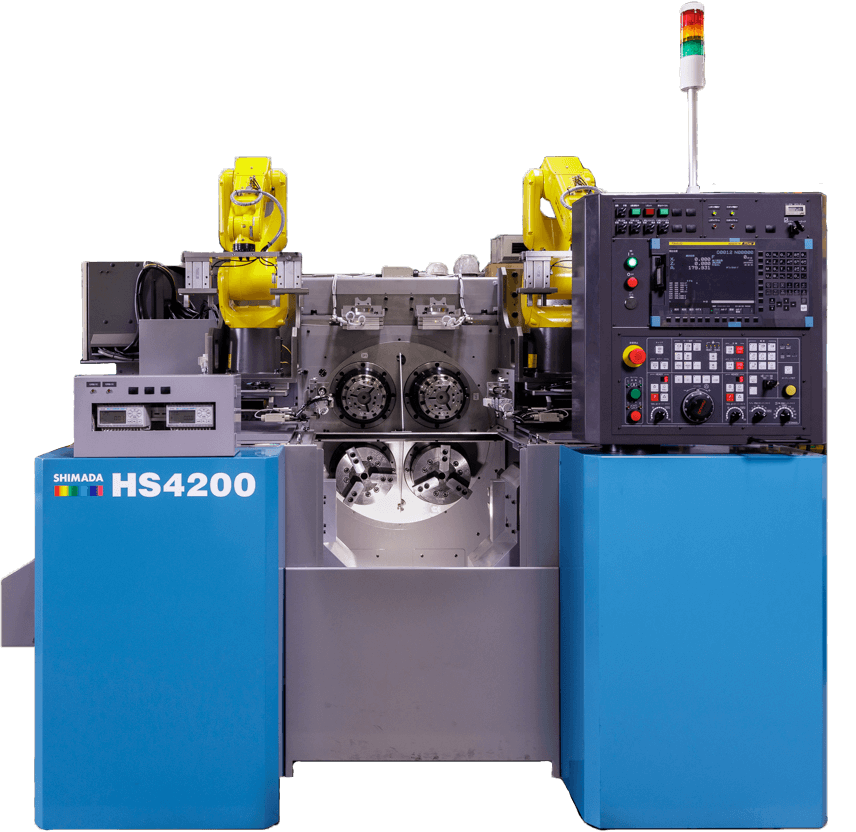

HS4200

This machine achieves ultra-high efficiency because it has four stations where machining processes OP10 and OP20, loading, and parts reversing are performed simultaneously.

-

VT4-350

A vertical type 4-spindle lathe is suitable for mass production of large parts that require longer Loading time.

Two machining processes can be performed at a single machine.

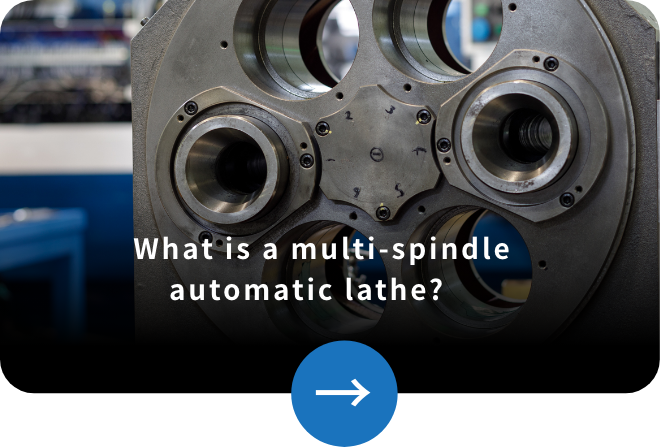

6-Spindle(6-Spindle automatic lathe)

Often called a multi-spindle automatic lathe. The entire process is divided into six steps which are performed at the same time. This significantly reduces the cycle time.

-

ISM B6-27NC

6-spindle lathe bar machine with a C-axis milling function.

High-end model equipped with a built-in spindle motor.

-

B6 series

This series is a 6-spindle lathe bar machine (with automatic bar feeder) and is available in three models depending on the bar diameter.

For small diameter<B6-16>

For medium diameter<B6-27>

For large diameter<B6-32> -

CN-660

The world’s first Multi-spindle lathe with CNC equipment developed and produced by Shimada.

-

CN-660 DSP

A 6-spindle lathe that specializing in machining irregular-shaped workpieces.

8-Spindle(8-Spindle automatic lathe)

A machine with eight stations divides the entire process into eight process.

-

SS-8

This machine uses eight spindles to divide the process into eight.

Rough machining is performed at the no NC slide, and finish process is at the NC slide.

Please contact us about reducing your cycle time.

-

INQUIRIES

Contact us by email

-

+81(0)0533-76-3381

Operating hours: 8 AM to 5:30 PM (Monday~Friday)