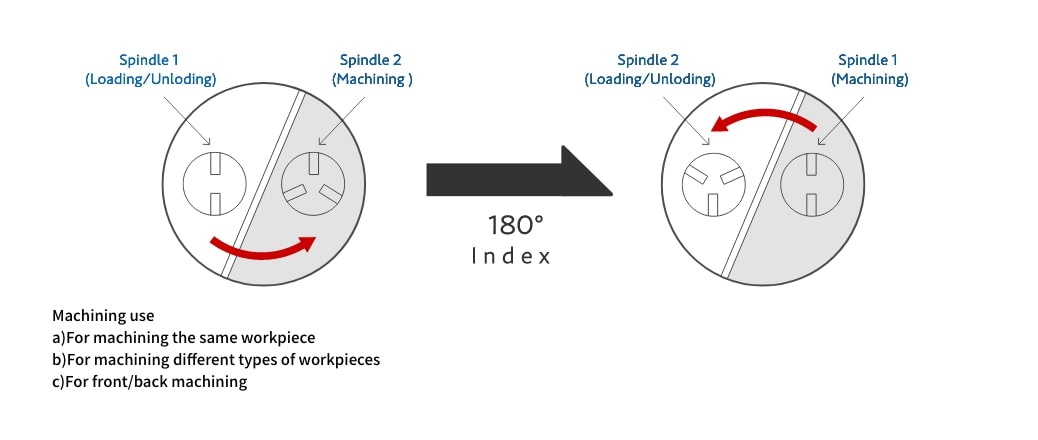

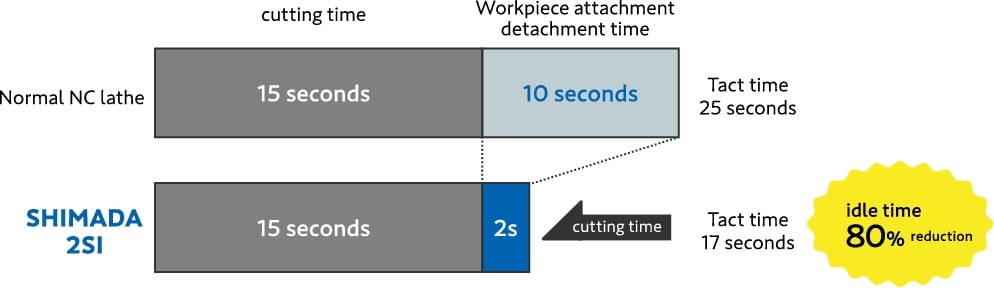

At the case of general NC lathe, the time for whole operations(loading, un-loading, air-blow, etc.) is added to the machining time, but at the case of 2SI, it is possible to shorten the tact time as each spindle shares the machining and loading/un-loading, and provides the simultaneous process.

For example, if it takes 15 seconds for the machining and 10 seconds for the loading/un-loading to work on 6-inch class small work, normally the total of these time, which is 25 seconds, will be the tact time. However, at the case of 2SI, 15 seconds of machining time plus few seconds of spindle drum index time can be the tact time, which is approx.17 seconds. (Ref. diagram.2)

In addition, 10-inch class big work and 1 meter long shaft work need much longer time for loading/un-loading at both case of using gantry loader and robot or using as a manual loading machine, so wide time cut will be possible.