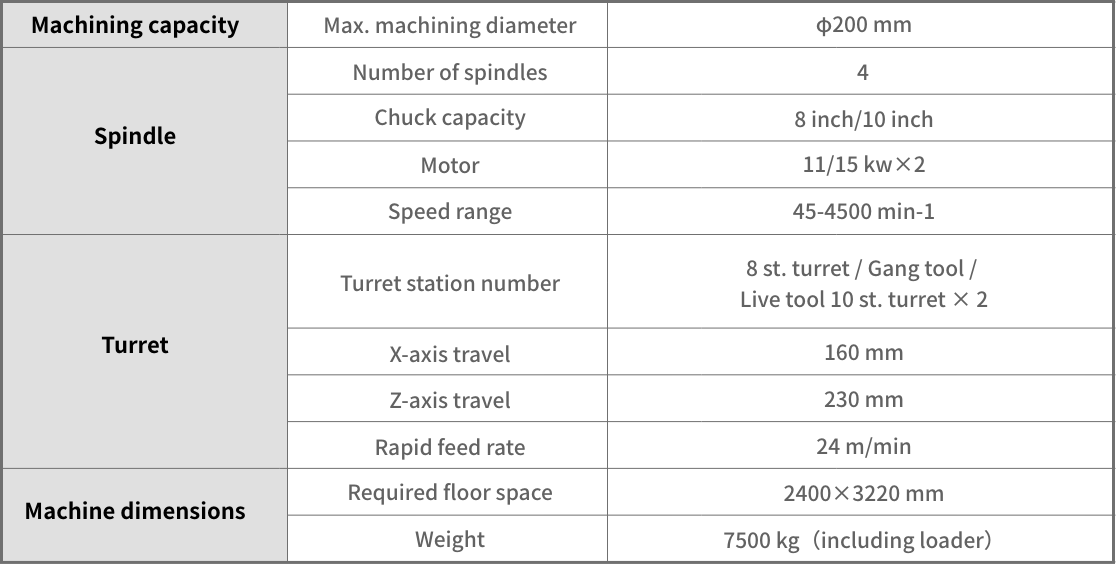

This 4-Spindle 2NC slide (4-spindle 2-turret lathe) can significantly reduce both the idling time and cycle time by cutting and loading/unloading the workpiece at the same time.

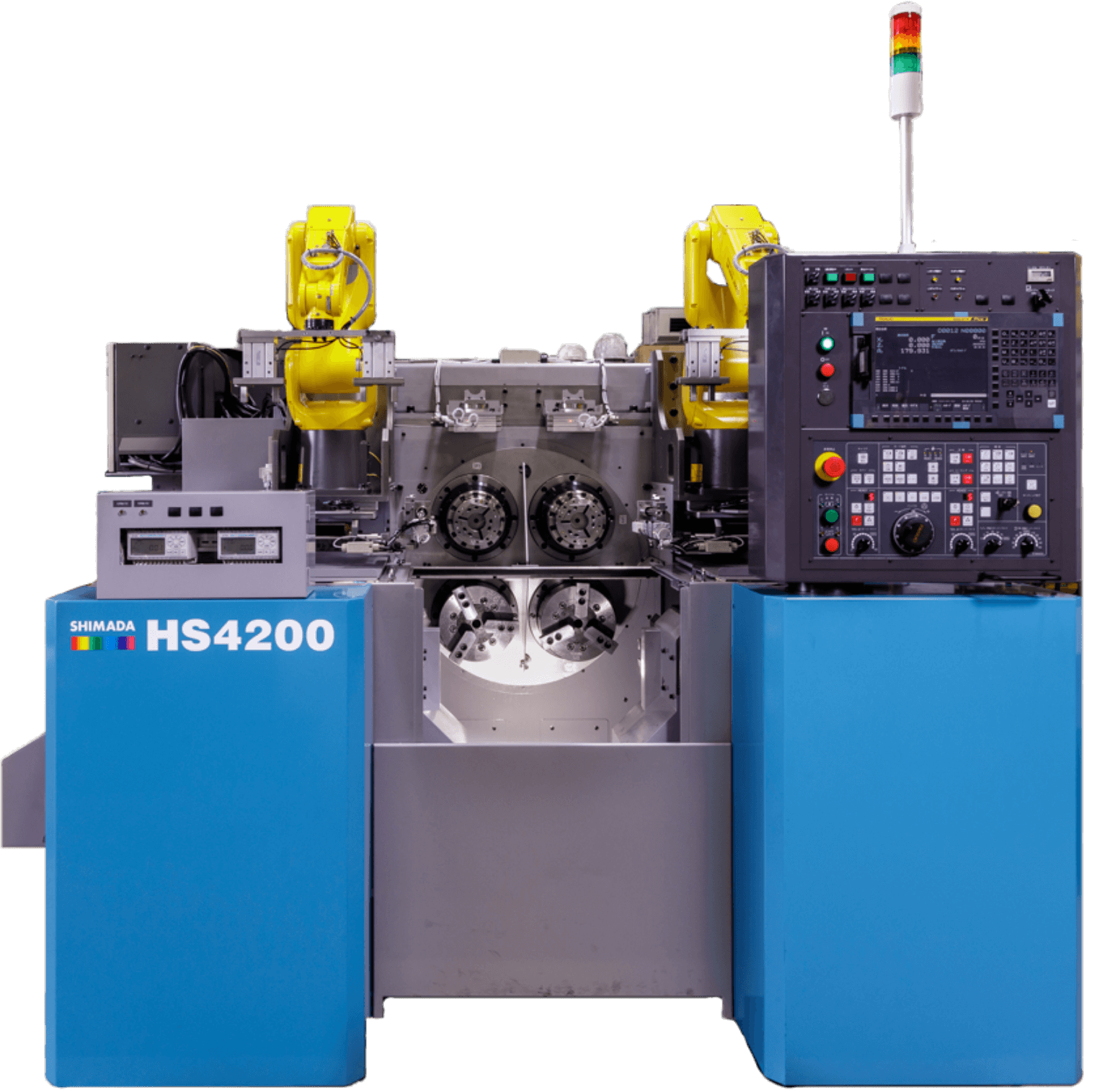

HS4200

4-spindle 2 turret

A machine that can effortlessly reduce cycle time without changing the machining conditions or loader speed.

MOVIE

-

Overview of 4-spindle 2 turret

-

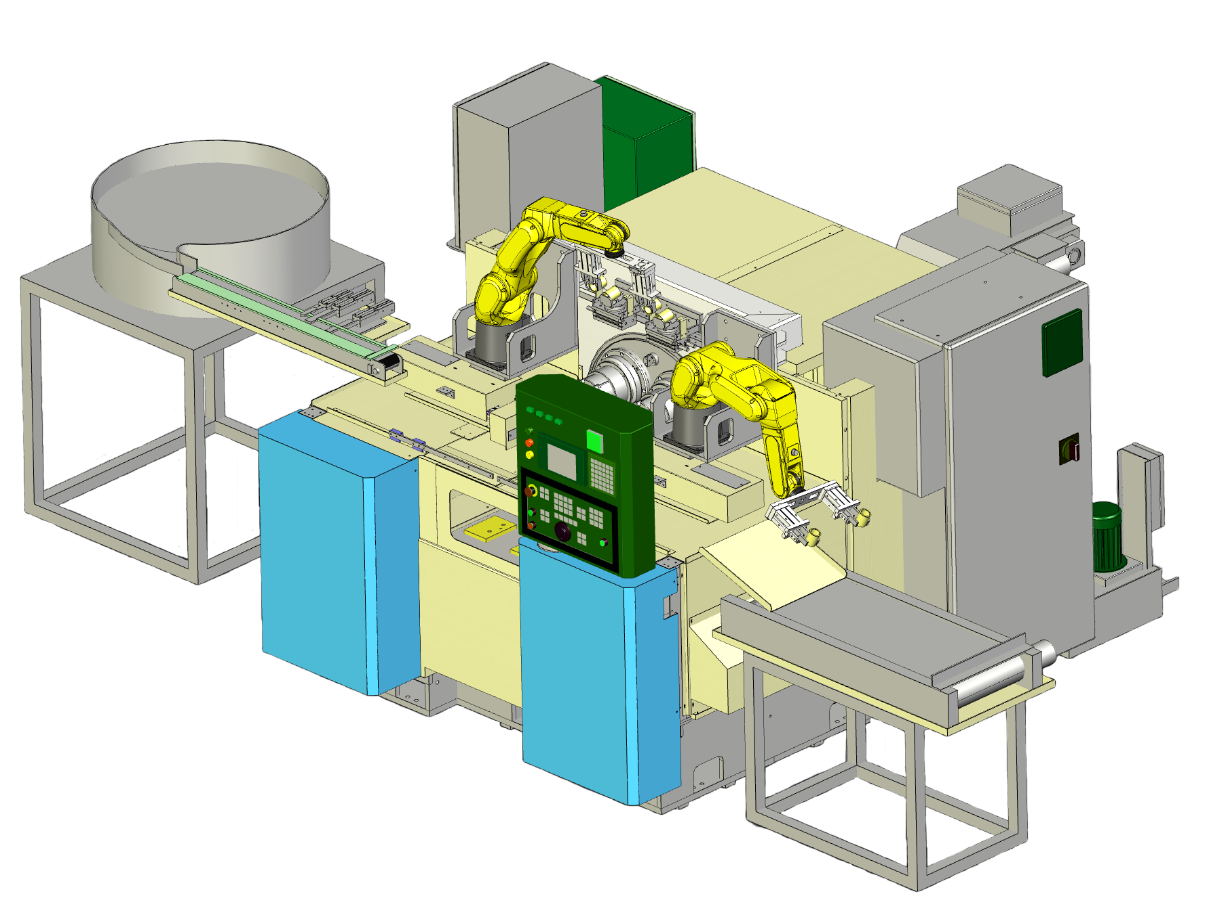

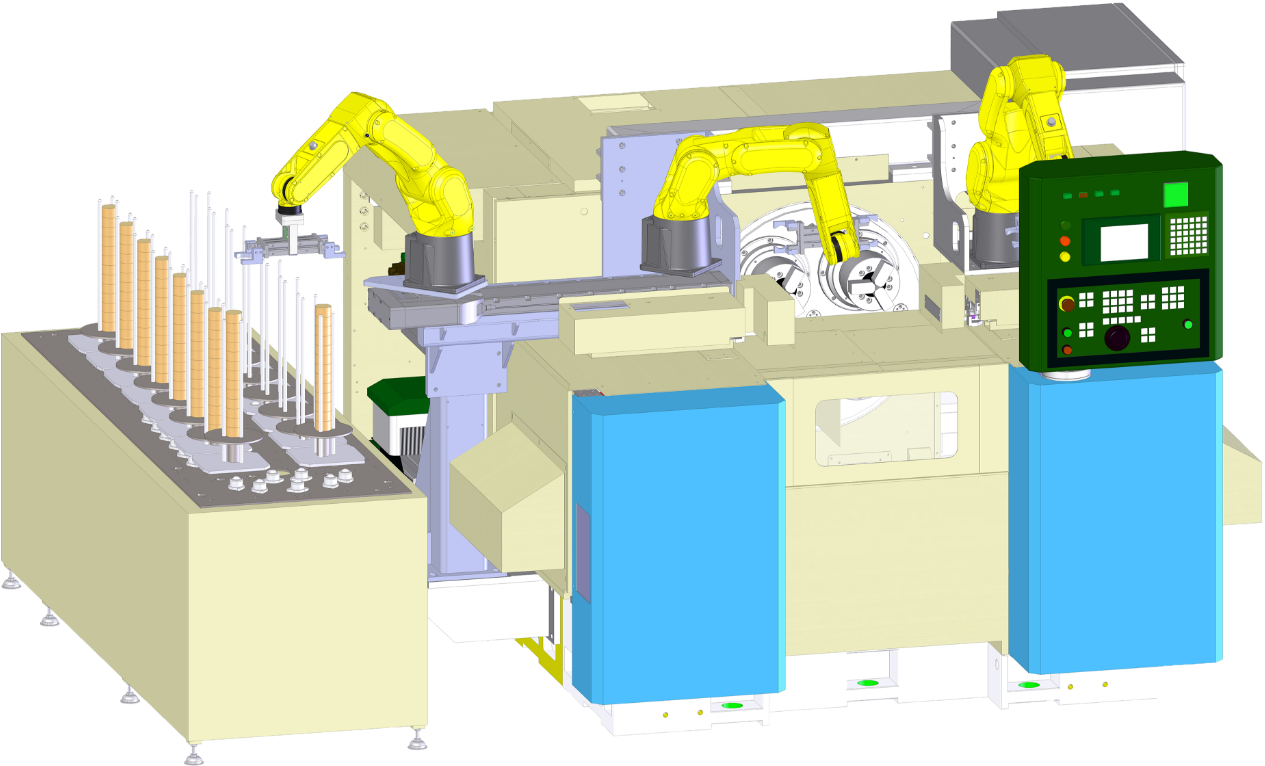

AA/BB with 2 robots

-

robot + vision system

FEATURES

-

01

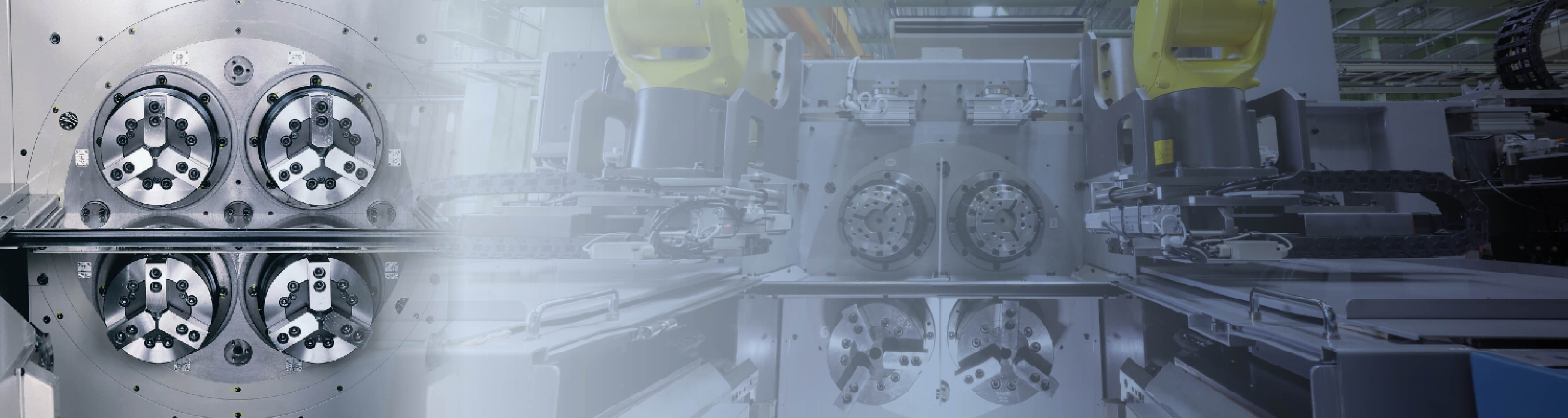

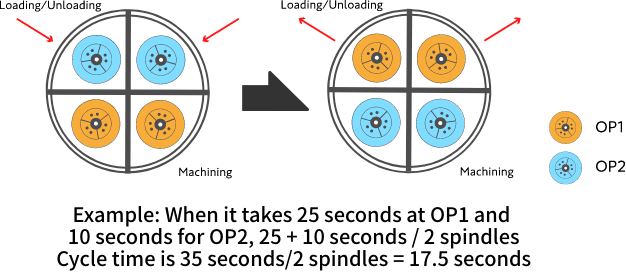

While the 1st and 2nd spindle are machining, the 3rd and 4th spindle are loading or unloading

▶Machining and workpiece loading/unloading are performed at the same time to achieve an effective loading time of zero seconds! -

02

There are four chucks so all four operations (Operation 1 (OP1), Operation 2 (OP2), inversion, and workpiece attachment) are gathered on a single machine and performed at the same time.

A lathe with a high operation rate close to 100% that is always creating chips, this significantly reduces the cycle time and improves productivity!

-

03

The spindle for loading and unloading the workpiece is exposed outside the partition door. The machine design enables easy chuck exchange and manual workpiece loading/unloading.

-

04

Automation is achieved with zero robot space because the robot can be mounted on the machine.

Loading the robot on the slide rail provides a stroke equivalent to a gantry loader.

Two types of time loss that can be resolved only by using a 4-spindle 2-turret machine

-

Loader idling time⇒ Eliminated by “Zero-second loading”, simultaneously performing machining and workpiece loading/unloading!

-

Difference in machining time between the 1st and 2nd processes (OP1 and OP2) ⇒ Resolved by alternating the 1st and 2nd machining (AA/BB processing specifications)!

4-spindle 2NC slide (Twin Turrets)

When there is a difference in the machining time for OP1 and OP2

⇒ AA/BB is the best solution.

AA/BB with two robots

SPECIFICATIONS