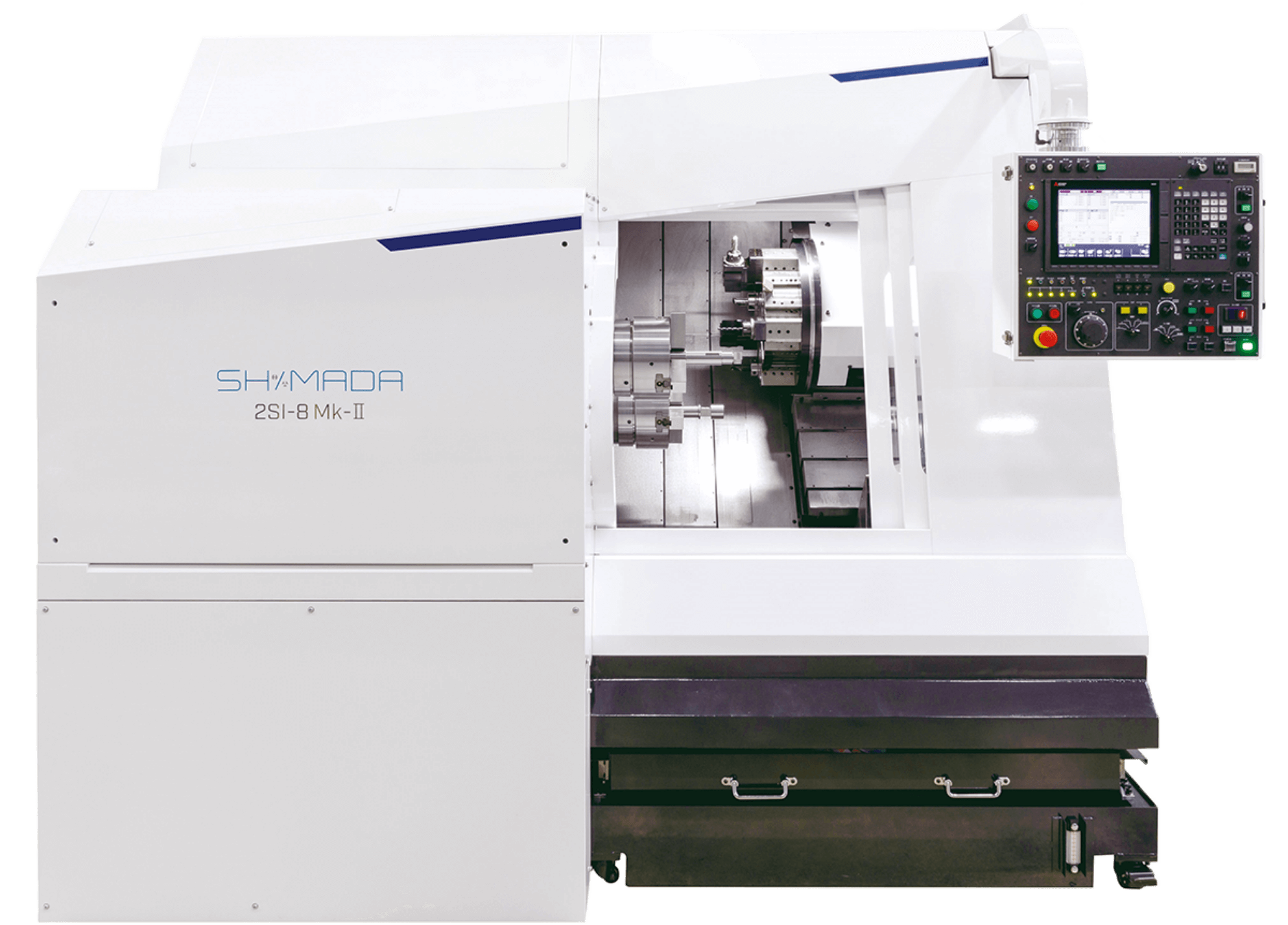

2SI-8 Mk-Ⅱ

While keeping the concept of “Absolute Zero-second loading Time” and “1st and 2nd Interprocess Machining,”

We outgrow from the oridinary through out-of-the box approach with advanced technology and fresh perspective that provides impressive innovation...

“2SI-8 Mk-Ⅱ” Development background

Our development started with the desire to solve certain problems that we observed at many manufacturing plants.

MOVIE

-

2SI-8 Mk-Ⅱ

FEATURE

-

01

Supports a wide range of conventional workpieces with the Y-axis, Driven tools, and a tailstock.

-

02

Chips are not produced for only 2.2 seconds! A machine with a cutting time ratio that is as close to 100% as possible.

The 1st spindle is machining while the 2nd spindle is loading and unloading. This achieves an effective loading time of zero seconds!

No chips are produced during the 2.2 seconds in which the door opens and closes and the table rotates 180 degrees.

-

03

There are two chucks, so a single machine can perform machining both on the front (OP10) and back (OP20) sides of the workpiece at the same time, resulting in process-intensive machining.

- Effect:

- No need to purchase two single-spindle NC lathes.

This halves the required number of machines and space, reducing equipment investment costs by a significant amount.

-

04

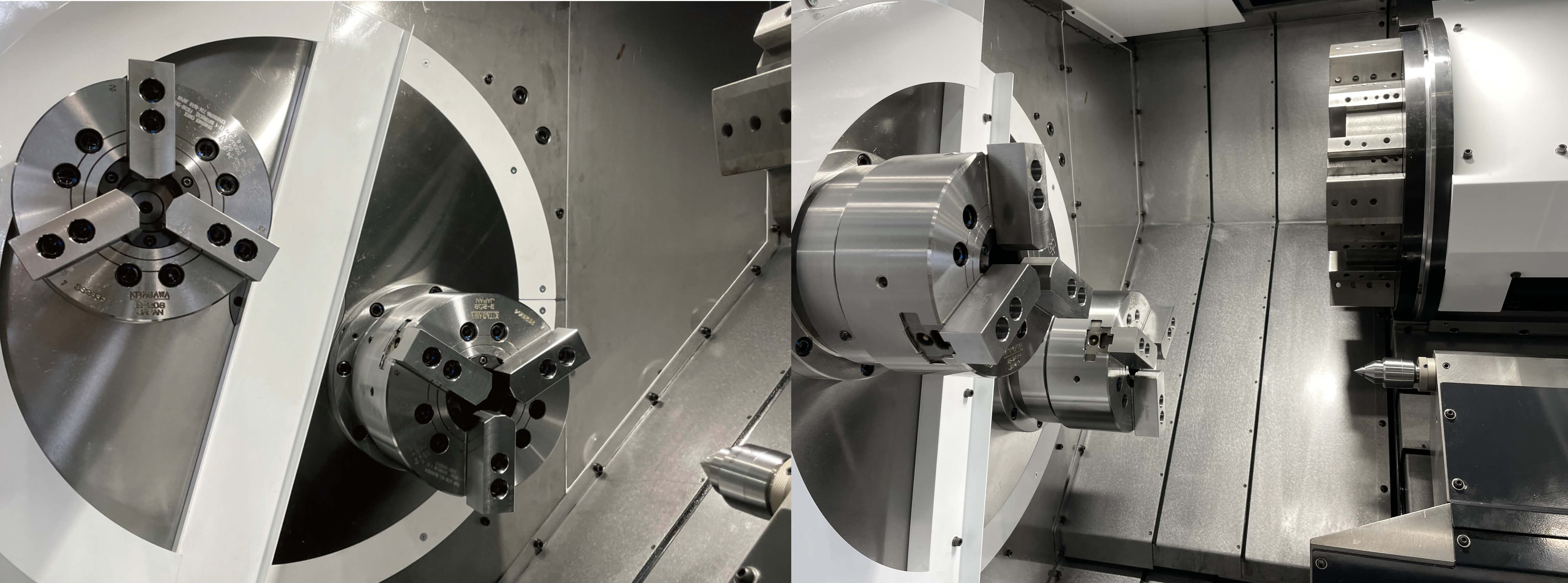

The unique external loading spindle design allows easy access to the chuck for part setup and manual loading with great ease.

- Effect:

- Chucks located outside the partition door enable easy robotic access, manual loading, and chuck changeover. The robot can be mounted on the machine, which also saves space.

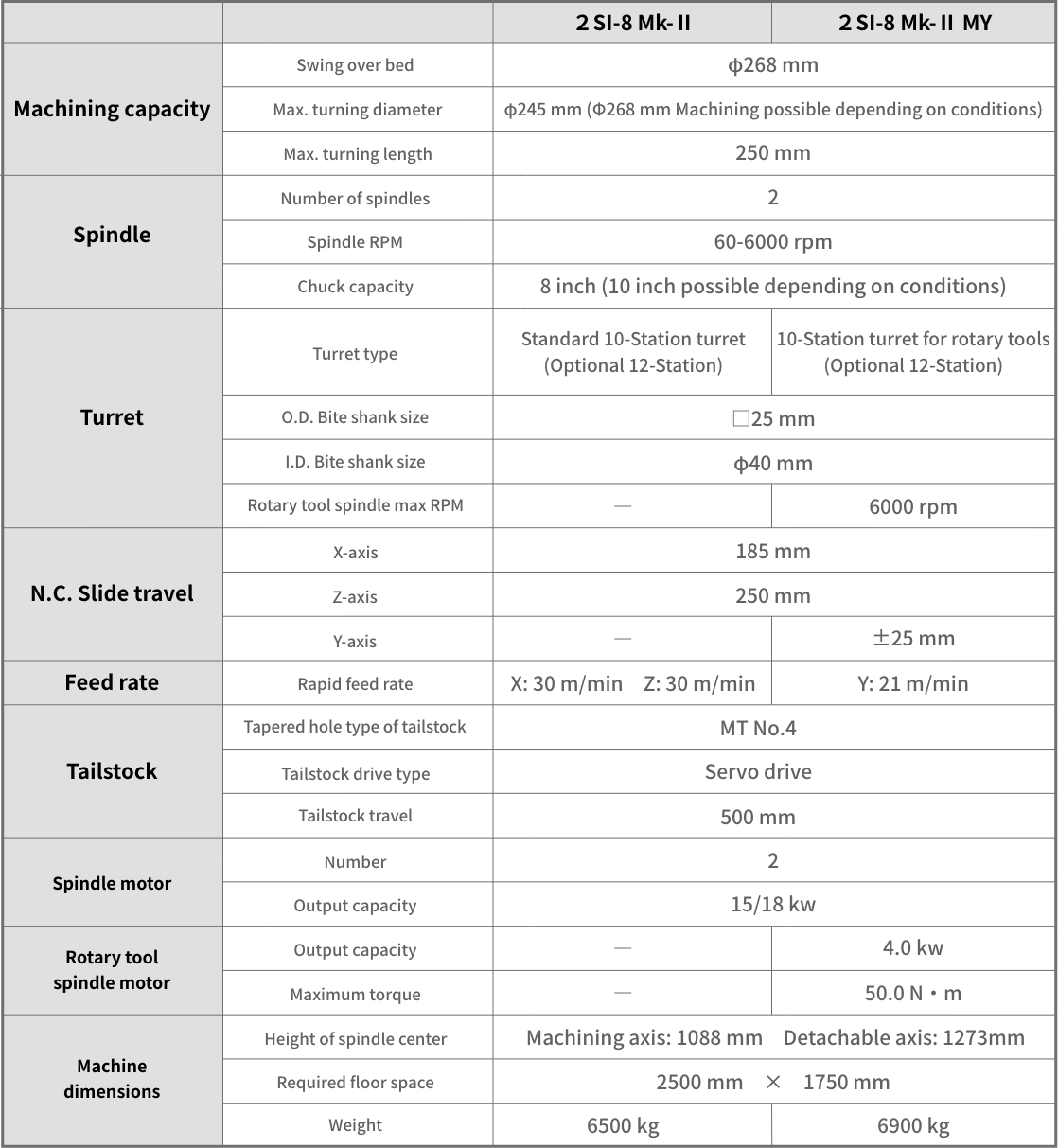

SPECIFICATION