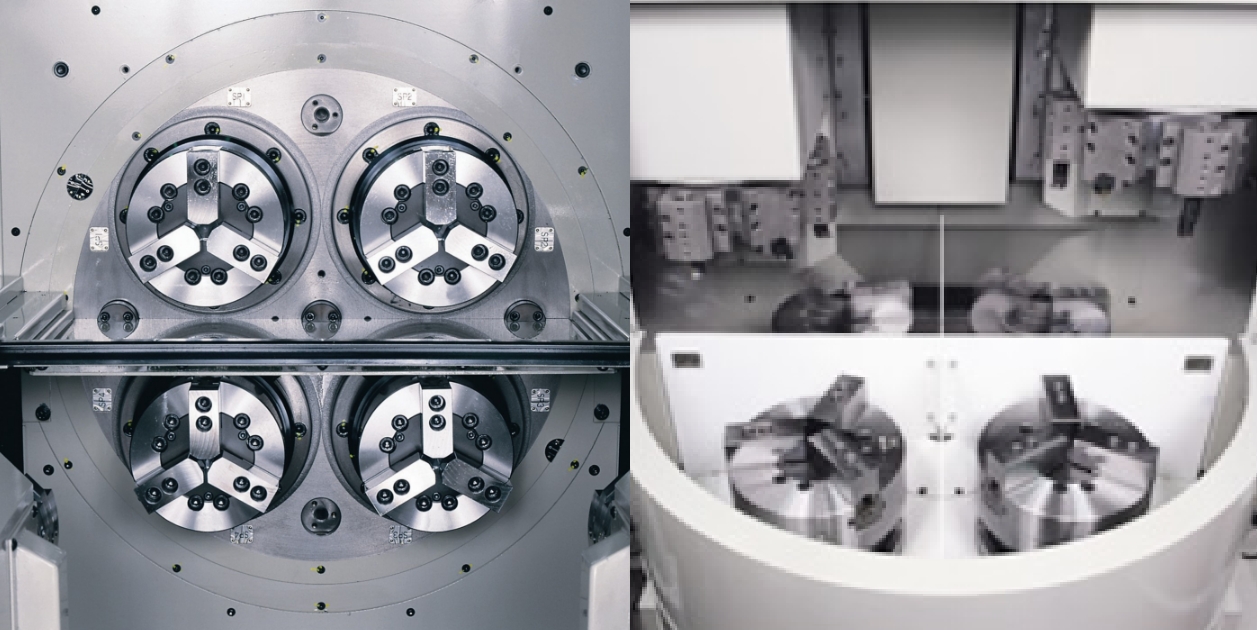

4-spindle+Twin Turrets

4 Spindle 2NC Lathe

Available in both horizontal and vertical models, and with more than 1,200 machines in service worldwide, the drawings, tooling, expertise, and manufacturing rights to the ultra-high production CNC lathes were acquired from Kitako Corporation, a division of Kitagawa Iron Works, in 2011.

About 4 Spindle 2NC Lathe

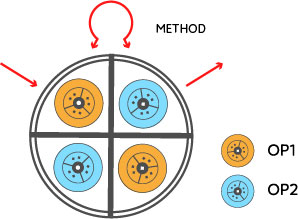

Part loading/unloading time can literally be reduced to ZERO.This type of machine has 4 spindle + 2 CNC slides. (2 spindles simultaneously machine while the other 2 spindles load/unload).

After finishing both operations, the spindle drum indexes 180°

*The actual idle time (machine down time) is just the carrier indexing time.

(HS4200:almost 1.5 seconds. VT4-350:almost 5 seconds.)

What are the characteristics of the 4 Spindle 2NC Lathe?

-

- A1

- Shortest idle time: even if you carefully and slowly load and unload the workpiece, blow air to the chuck, measure dimensions, etc., the cycle time will not increase as long as it is within the processing time.

-

- A2

- One unit can perform four roles at the same time: surface processing, back processing, loading, unloading, and reversal = high productivity in a small space.

What parts are suitable for the 4 Spindle 2NC lathe?

-

- A1

- When loading time is longer than machining time:

Example)

Machining = 40 sec. Loading = 40 sec

Machining = 10 sec. Loading = 10 sec.

-

- A2

- When there is a large difference between OP1 (front) and OP2 (back) machining time:

Example)

OP1 = 25 sec. OP2 = 10 sec.OP1

-

- A3

- High precision and mass production parts.

-

- A4

- In case of long chucking times, such as with big, long-shaft, irregularly shaped parts, the VT4-350 especially is the best solution for big parts with long loading times. → VT4-350

Various machining methods

-

Front and back reversal processing (AB/AB method)

Front and back side operation

If the processing time for OP1 and OP2 is approximately the same

-

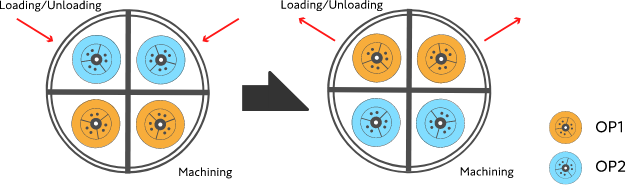

Front and back reversal processing (AA/BB method)

If there is a difference in machining time between OP1 and OP2

Example: When it takes 25 seconds for OP1 and 10 seconds for OP2, cycle time is 35 seconds/2 spindles = 17.5 seconds

-

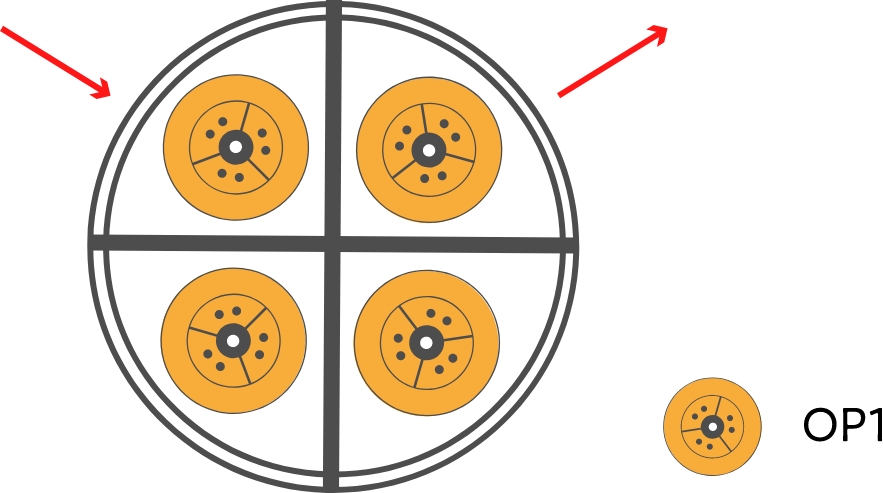

Simultaneous processing of 2 pieces (2 pieces in, 2 pieces out, AA/AA method)

If only one side (OP1) is processed, two finished products can be produced per cycle.

Example: If one workpiece takes 25 seconds, cycle time is 25 seconds/2 pieces = 12.5 seconds