Multi-spindle automatic lathe

What is a multi-spindle automatic lathe?

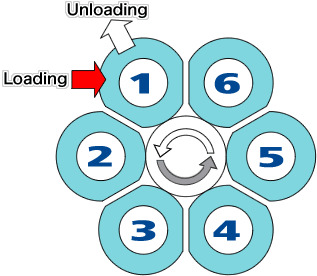

Multi-sindle automatic lathes (multi-spindle screw machines) can provide various types of machining such as boring, turning, chamfering, threading, grooving, and drilling by moving the workpieces between 6 or 8 positions (machining positions). This machine tool enables overwhelmingly fast cycle times by dividing processes into six or eight steps.

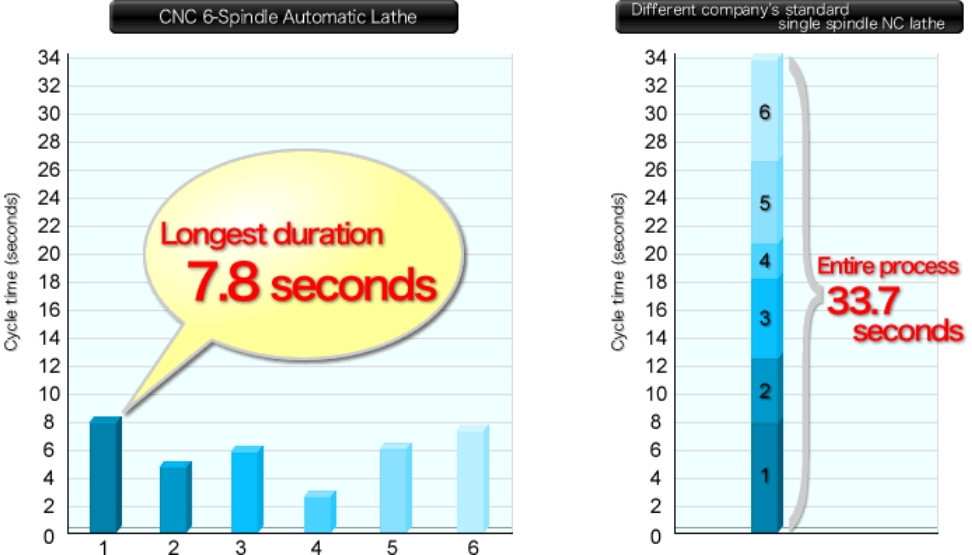

In general, multi-spindle automatic lathes can provide approximately 4-5 times the machining speed of single-spindle NC lathes, although the speed can be widely addjusted depending on various conditions.

Here is a more precise explanation on how such fast cycle times are possible.

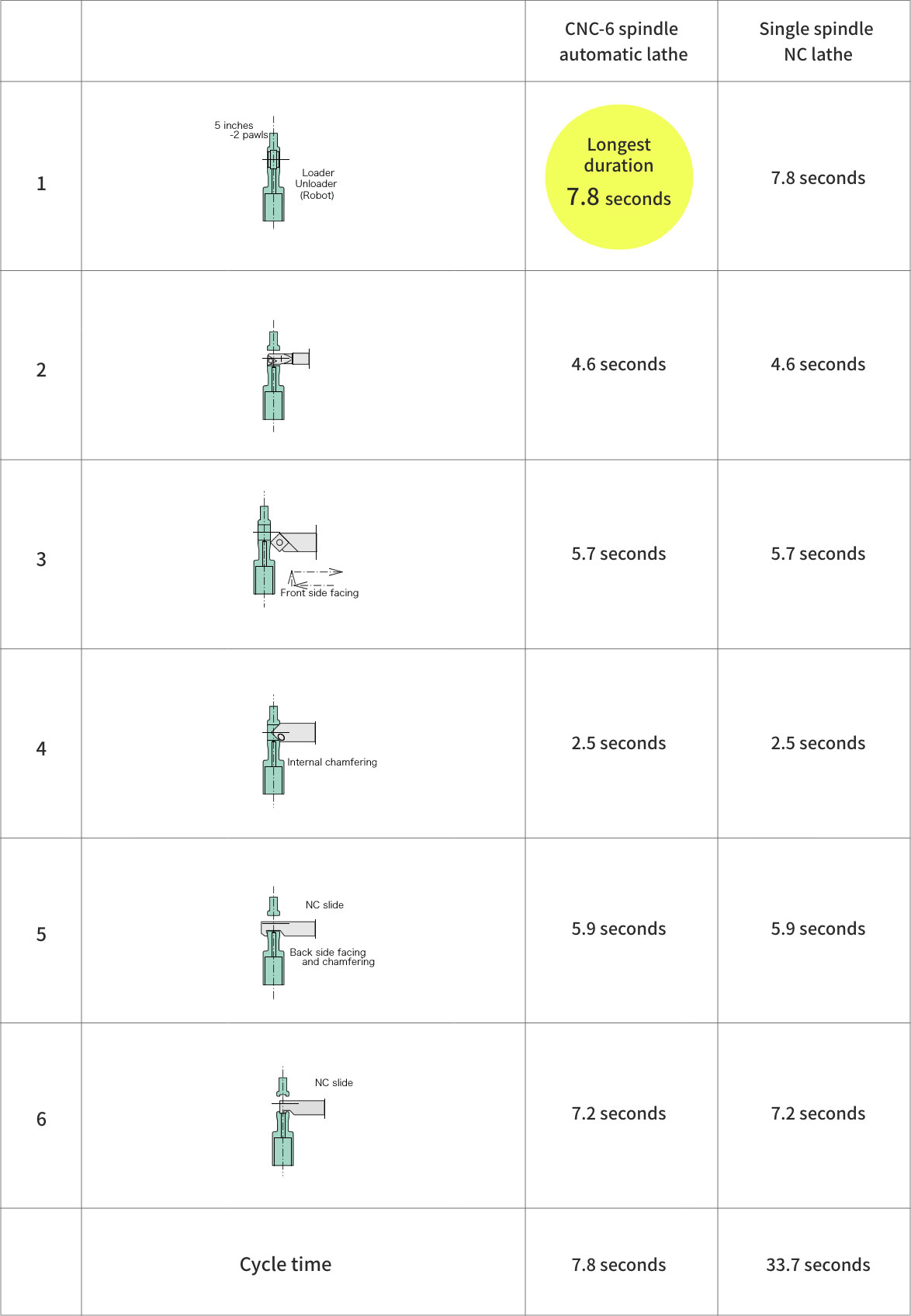

The process is divided into 6 steps as shown in the tooling layout below. In this whole process, Pos. 1 (loading/unloading) takes the longest time. With a 6-spindle automatic lathe (6-spindle screw machine) or 8-spindle automatic lathe, this longest position time is equal to the cycle time.

On the other hand, with a single-spindle lathe, the cycle time is the sum of the duration of the whole process, as in this case, each process is not divided into several steps.

As shown in the tooling layout below, SHIMADA’s 6-spindle automatic lathe takes 7.8 seconds, while other companies' single-spindle lathes take 33.7 seconds, which means SHIMADA’s 6-spindle automatic lathe can perform the work of 4.3 single-spindle machines.

CNC Multi Spindle Automatic Lathe

With a 6-spindle automatic lathe, one spindle is used for loading and unloading, and the other five spindles are used for machining. SHIMADA’s 6-spindle automatic lathe can have 3NC slides attached and the 8-spindle automatic lathe can have 2NC slides attached.

The rough machining is performed at non-CNC slide positions and proceeds to the finish machining at one or more NC positions, therefore enabling high-speed and high-precision processing with this machine.

-

Sample Movie