Multi-spindle machines (multi-spindle automatic lathes)

SHIMADA specialises in the full range of multi-spindle solutions.

can divide whole processes into as many steps as the number of spindles!

This achieves incredibly fast machining and short cycle times.

Multi-spindle machines(Multi-spindle automatic lathe) can divide whole process into as many steps as the numbers of spindles!

This achieves an incredibly fast machining speedand short cycle time.

SHIMADA's Uniqueness

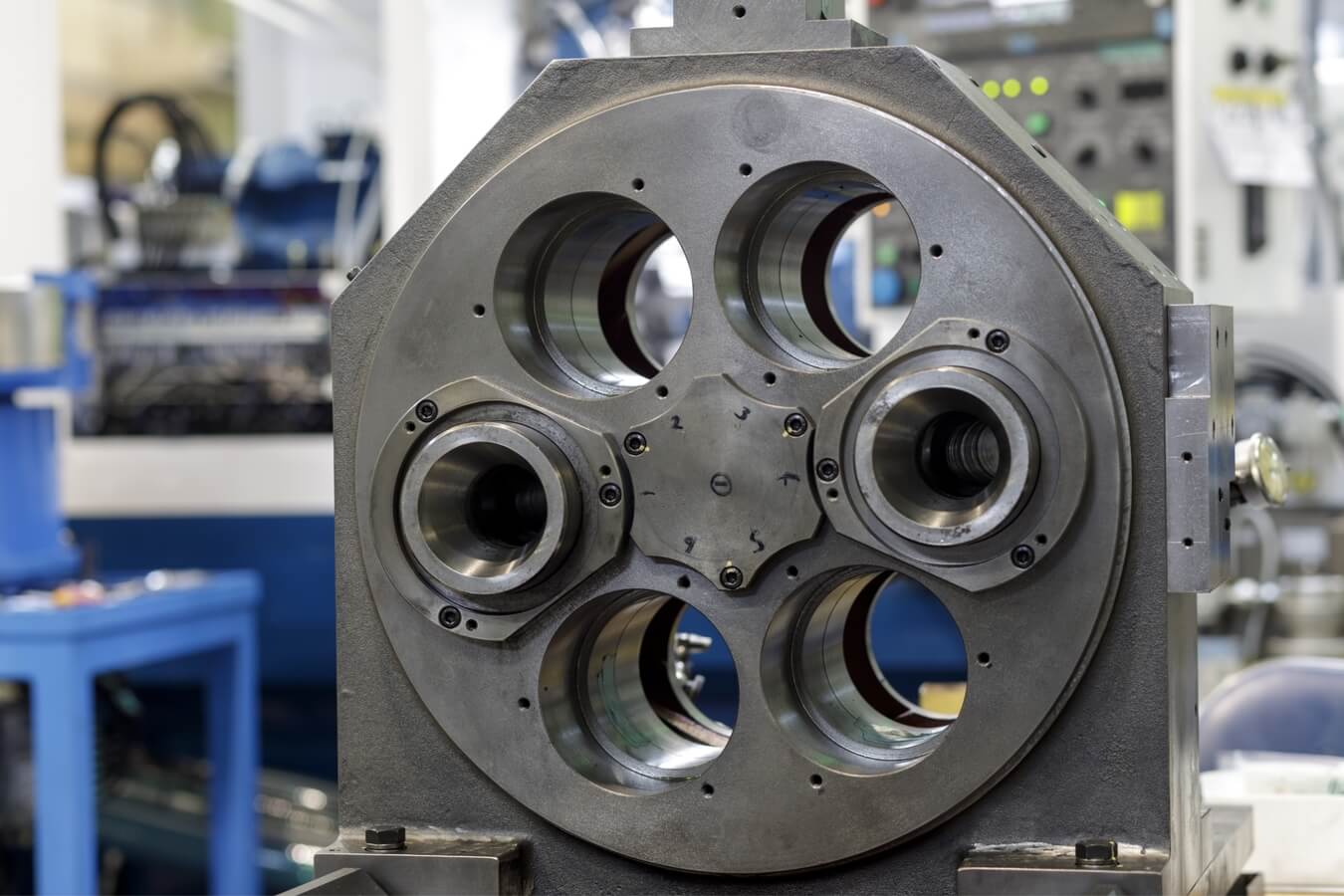

Dividing whole process into as many steps as the number of spindles

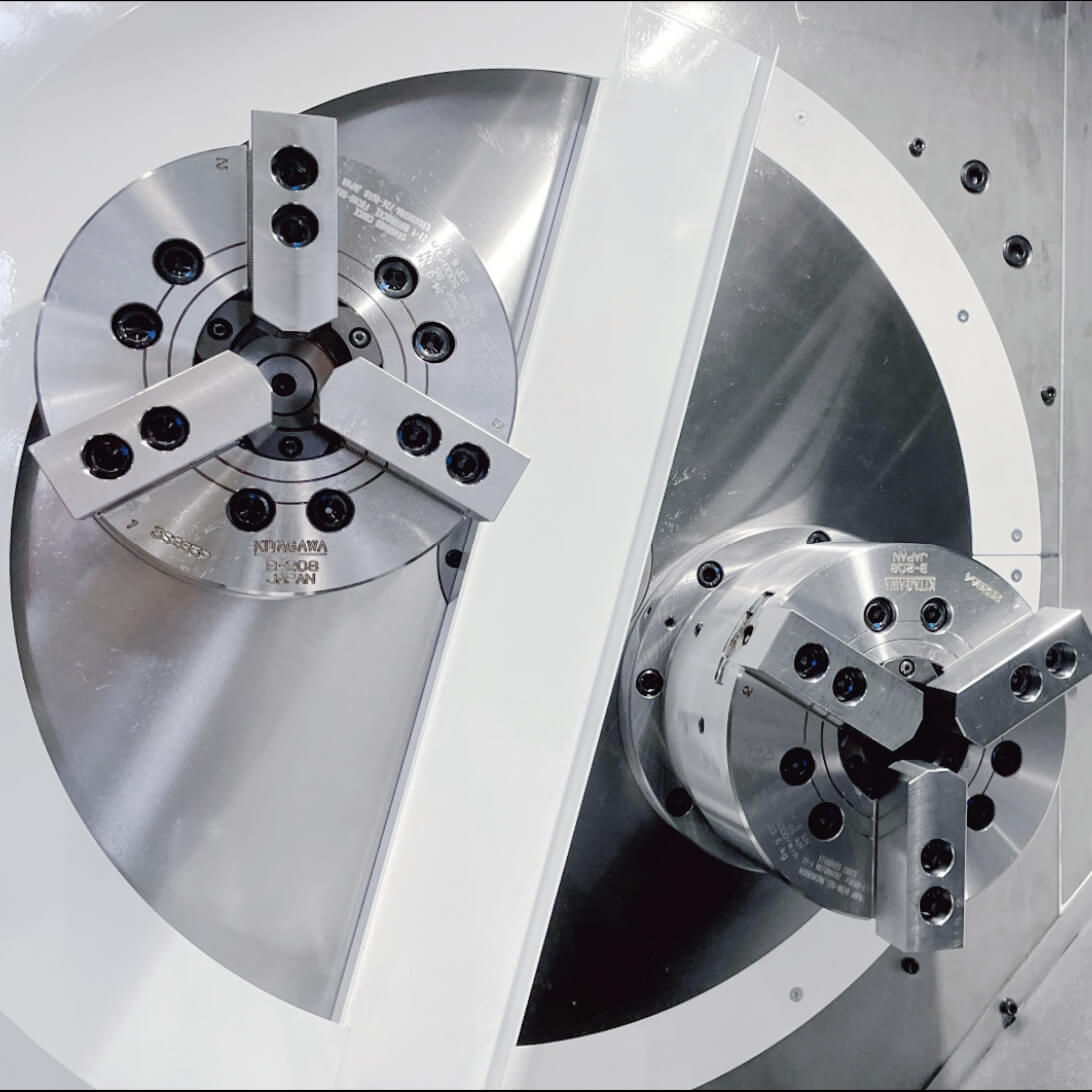

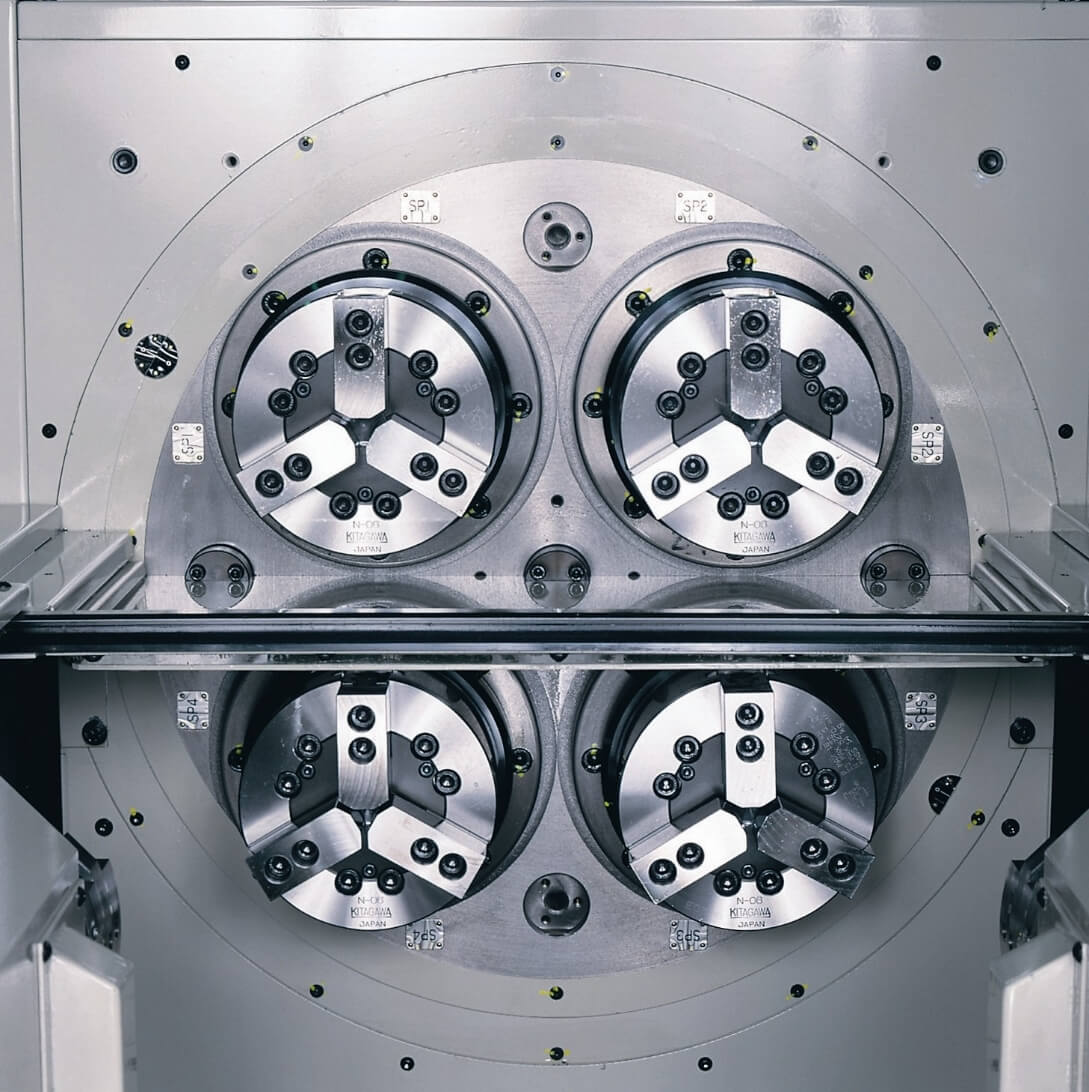

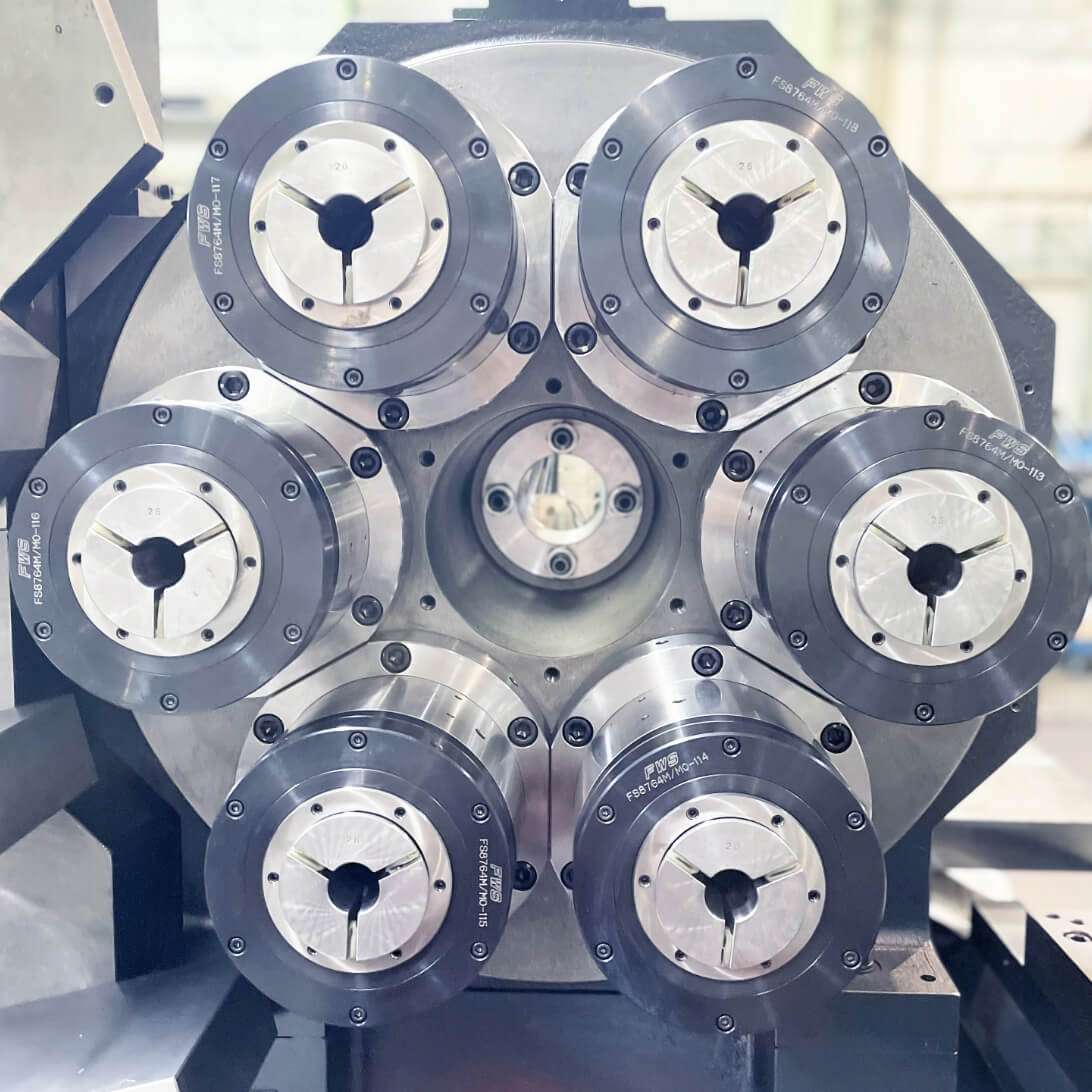

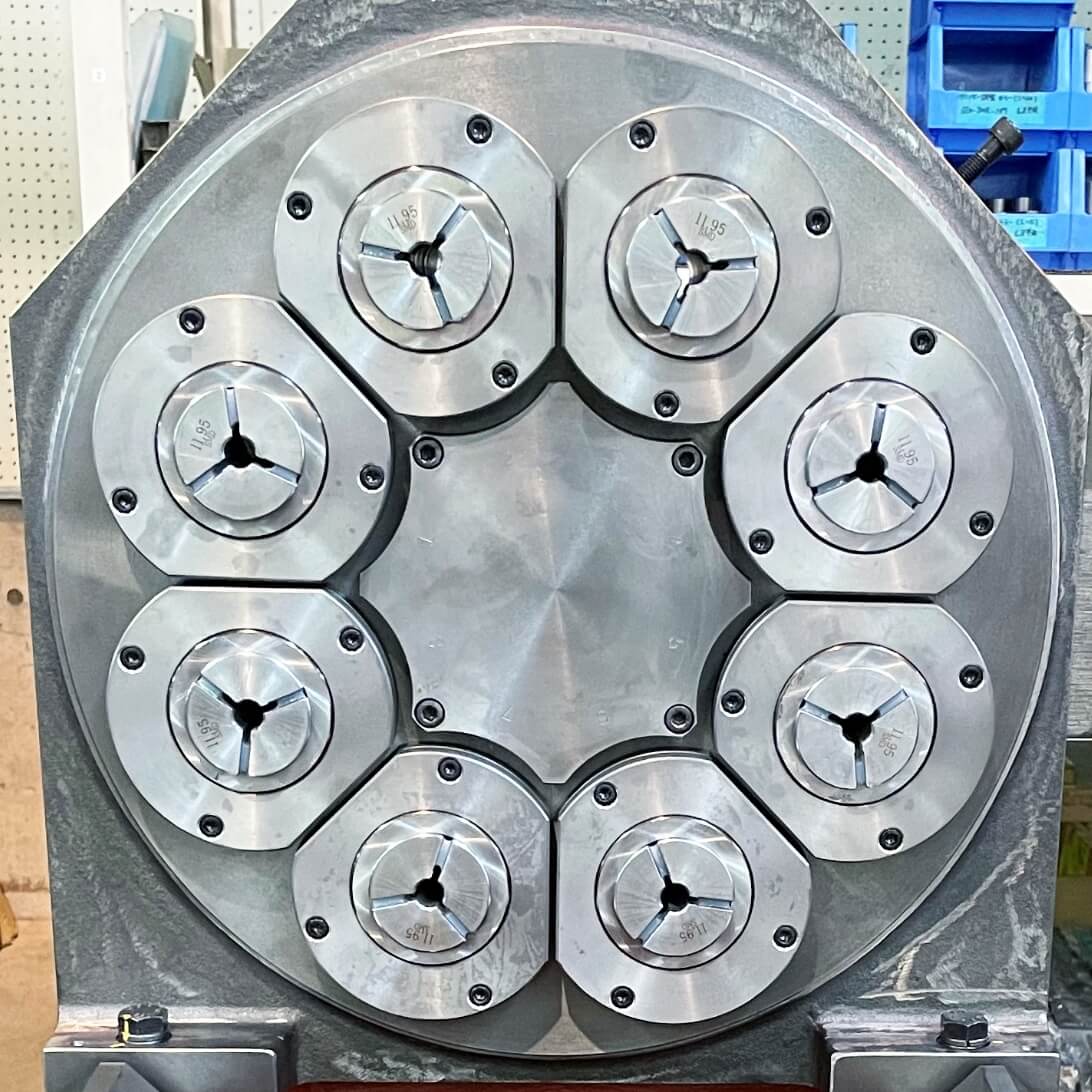

The housing case that stores each spindle is called a spindle drum or spindle carrier. The most important part of a multi-spindle machine, it is responsible for long-term machining accuracy.

The entire process is divided into n equal steps equivalent to the number of spindles available, then each step is started simultaneously to maximize the machining speed and production efficiency.

One-stop specialist for multiple spindles

We can propose the best model from our extensive multi-spindle machine lineup, which ranges from 2- to 8- spindles to meet your requirements for workpiece shape, production volume, machining conditions, and automation.

We believe SHIMADA is the only company in the world that specializes in multiple spindle machines, offering an extensive product lineup with 2, 3, 4, 6, and 8 spindles.

This shows SHIMADA’s uniqueness and originality.

Two areas of superiority

01

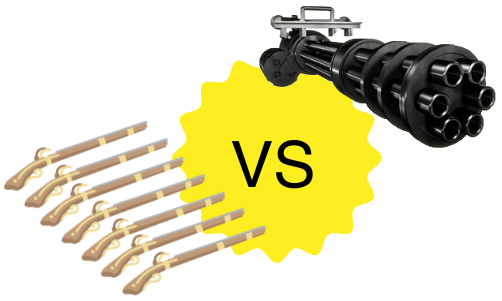

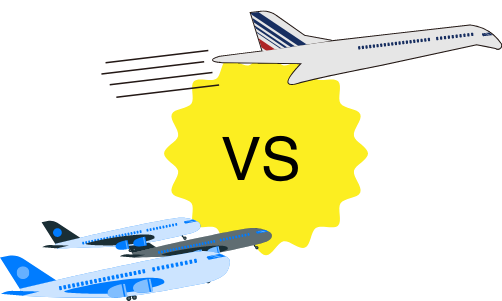

Superior speed

-

Matchlock vs automatic rifle

-

CONCORDE vs other airplanes

Higher speed allows machining process to be finished in a shorter time

An example of this is comparing the CONCORDE aircraft that flew from 1976 to 2003 with a standard airplane.

-

CONCORDE: Mach 2≒2,179 km/h

-

Other airplanes: Mach 0.8=870 km/h

The difference in speed resulted in 2.5 times shorter flight time.

A higher speed can produce greater volume in the same amount of time

An example of this is a matchlock that fires a bullet then requires several tens of seconds until it can be fired again against a machine gun that can fire over 100 shots per minute. This difference in speed shows that a few or a dozen matchlocks (standard single-spindle NC lathes) are required to produce the same results as a single machine gun (multi-spindle automatic lathe) .

02

Superior automation technology

The 6-spindle and 8-spindle lathes can, in faster cases, achieve a cycle time of three or four seconds. Transfer equipment, automatic loaders, and chucking mechanisms must keep the same pace to ensure that such short cycle times are achieved.

The spindle drum indexing type 2-spindle, 3-spindle, and 4-spindle NC lathes are highly compatible with robots. We specialize in building all-in-one lines in combination with stockers, measuring devices, and palletizers.

SHIMADA’s superiority lies in its loader and transport technology which does not lag behind the three- to four-second cycle time, and also in its automation and programming technology that makes free use of robots.